| PRODUCTS |

COMPONENT |

APPEARANCE |

APPLICATION |

| XLT-F-1310 |

combination of fatty acid salts and calcium stearate, free of mineral fillers |

white to yellow dispersion |

Mixing process, dipping baths, and batch-off equipment |

| XLT-F-1312 |

aqueous dispersion of a combination of fatty acid salts, free of mineral fillers |

white to yellow viscous liquid |

Mixing process, dipping baths, and batch-off equipment |

| XLT-F-1313 |

aqueous solution of a combination of fatty acid salts, contains no pigments |

white to yellow viscous liquid |

Mixing and extruding processes; highly soluble |

| XLT-G-1001 |

very fine-particle zinc stearate, dispersed in water |

stable white suspension, low viscosity |

Mixing process, dipping baths, and batch-off equipment, preparation of blanks in Barwell extruders; low viscosity, can be diluted directly to required concentration |

| XLT-G-1002 |

aqueous suspension of particularly fine zinc stearate |

stable white suspension |

Dipping baths, batch-off-lines, for the production of blanks in Barwell extruders |

| XLT-100 |

combination of fatty acid esters with inorganic carriers |

light-yellow granules |

Provides processing improvement and better dispersion for all kinds of technical molded and extruded goods. Usually used in carbon black loaded compounds |

| XLT-200 |

blend of fatty acids, fatty alcohols and fatty esters |

light-brown to brown pastilles |

For all rubbers including EPDM and CR. For molded and injected technical articles of all type, footwear. For continous vulcanization processes (LCM,UHF) and injection molding |

| XLT-300 |

anhydrous blend of fatty alcohols and fatty acid esters |

light-brown to brown pastilles |

Application in continous vulcanization processes (LCM,UHF) and injection molding.Technical rubber goods, e.g. profiles |

| FL |

mixture of high molecular weight fatty acid salts and hydrocarbon polymer |

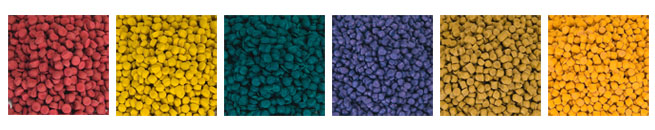

claybank particles |

Rapidly reduce the viscosity of rubber compounds and improve the dispersion of fillers, so as to stabilize the compound quality from batch to batch. As a result, it especially suits for the extrusion process, as well as injection transfer moulding and transfer moulding cure. Its zinc content will also be used as curing activator to reduce the dosage of stearic acid. |

| AD-80R |

|

yellow granules |

Containing no lead, cadmium or any other poisonous chemical compounds; rapid decomposition under low temperature; quick dispersion, high efficiency, low loss, excellent stability |

| CR-50E |

|

white granules |

Titanium dioxide masterbatch for EVA foaming |

| KCB-20 |

|

white granules |

Masterbatch of whitening agent |